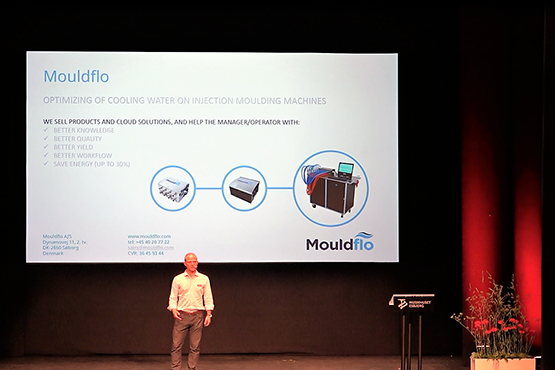

Mouldflo saves energy

Growth strategy and innovation

Mouldflo offers a plastic injection for the molding industry. An intelligent manifold solution for monitoring flow, temperature and pressure of cooling circuits within a mould – and a validation tool for mould makers. The solutions were created to reduce cycle-time, improve energy savings and increase productivity.

“Moludflo applied for participation in the Next Step Challenge because we wanted a better understanding of our own opportunities in the market and to be inspired to create additional business models. At the same time, as a new team, we needed a concrete growth strategy, which should be based on user-driven innovation,” explains Thor Mønsted, Director in Mouldflo.

See the program Mouldflo attendedWe moved our "self-understanding" from levels 3 to 8, says the Mouldflo team.

Advisory Board

“Our Next Step Challenge Advisory Board helped us launch a concrete, practical and investigative process that gave us a great deal of answers to the questions we had. And we have defined more business models, a specific product development plan, a prioritized action plan, and moved our “self-understanding” from levels 3 to 8,” says Thor Mønsted, Director in Mouldflo.

The advisory board for Mouldflo:

John Hansen – SVP Engineering & Corporate Quality – LEGO

Claus A. Nielsen – Director of Technology – Din Forsyning